New Hydrogel Hybrid Could Be Used To Make Artificial Skin

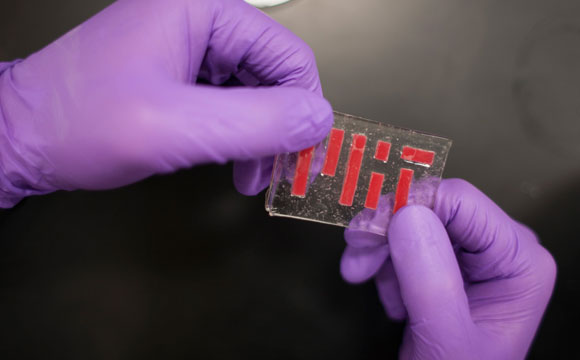

MIT engineers have developed a method to bind gelatin-like polymer materials called hydrogels and elastomers, which could be used to make artificial skin and longer-lasting contact lenses.

If you leave a cube of Jell-O on the kitchen counter, eventually its water will evaporate, leaving behind a shrunken, hardened mass — hardly an appetizing confection. The same is true for hydrogels. Made mostly of water, these gelatin-like polymer materials are stretchy and absorbent until they inevitably dry out.

Now engineers at MIT have found a way to

prevent hydrogels from dehydrating, with a

technique that could lead to longer-lasting

contact lenses, stretchy microfluidic devices, flexible bioelectronics, and even artificial skin.

The engineers, led by Xuanhe Zhao, the

Robert N. Noyce Career Development

Associate Professor in MIT’s Department of Mechanical Engineering, devised a method to robustly bind hydrogels to elastomers — elastic polymers such as rubber and silicone that are stretchy like hydrogels yet impervious to water. They found that coating hydrogels with a thin elastomer layer provided a water-trapping barrier that kept the hydrogel moist, flexible, and robust.

Click here to read more...